Technology & advantages

Learn more about the integral components of our ceramic heating elements.

Technology / Details

Our Technology

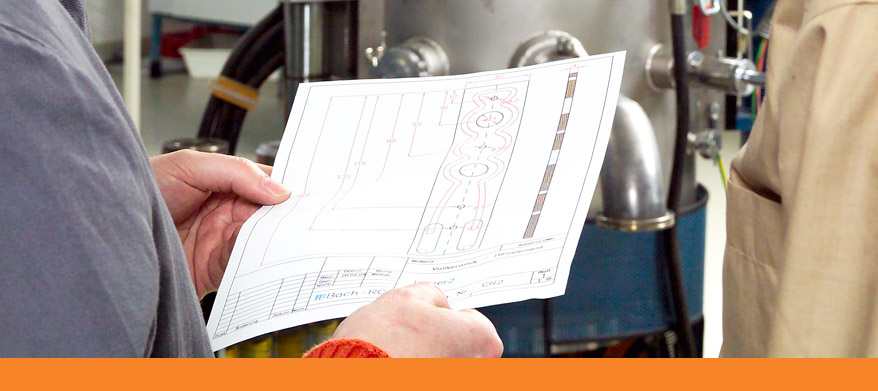

With our own patented technology for the production of 100 % ceramic heating elements featuring an integrated ceramic-heating conductor, our company Bach Resistor Ceramics GmbH has grown from a research lab into a medium-sized corporation, active across the globe.

Our 100% ceramic heating elements made from silicon nitride and aluminum nitride have a number of advantages in comparison to conventional metallic heating elements. Owing to its low-density, ceramic material has a low heat capacity and therefore is well suited to handle temperatures up to 1 000 °C with very little energy consumption. This extraordinary technology, which implements ceramic material able to conduct electricity uniformly sintered with an insulated ceramic housing, is able to deliver high performance consistently.

Highly resistant to wear and oxidation, these ceramics guarantee outstanding durability and long life as well.

The production process allows great versatility in creating a wide range of sizes and shapes. Heating capacity can thus be integrated into all kinds of durable ceramic parts, like cutting tools, welding brackets and other tools.

Due to the hardness of ceramic material, it can only be processed using diamond tools or lasers. Drilled holes, cutouts, vacuum grooving and other design features can all be included.

Advantages include

- high surface performance of up to 150 W/cm2 and radiation emission ε > 0.9

- temperatures up to 1 000 °C, short heat-up times, low residual heat, very good control accuracy thanks to low thermal mass

- outstanding durability at high temperatures

- resistant to oxidation, acids, corrosive gases, minimal wetting with liquid metals

- remarkable mechanical strength, good thermal conductivity, high insulation resistance and dielectric strength

- considerable hardness and wear resistance

Advantages in comparison

The high compressive strength of 2 000 MPa and the high Young’s modulus of 300 GPa of the Silicon nitride ceramic material are maintained at temperatures up to 1 000 °C. There is hardly any self-deformation.

- temperatures up to 1 000 °C

- remarkable mechanical strength

- integrated vacuum channels/drilled holes

- heated areas from 1 mm2 up possible

- heated area formed to the contour of the product to be heated